Boosting collaboration for supply chain LCA

As a manufacturer, you want to know what your suppliers are doing, and how, so you can fully understand the environmental impacts of your products. But for your suppliers, sharing this information can be very detrimental to their negotiating position. How do you cross that gap in perspective, so you can do reliable, robust supply chain LCA?

Outsourcing – a hurdle to transparency in the supply chain?

The globalised supply chain brings important financial gains for manufacturers, as both they and their suppliers can concentrate on what they do best: designing and building the components for products. Unfortunately, outsourcing means a blurred vision on the processes and material that go into your products.

When manufacturers were doing everything in-house, knowing the exact details of a process was a matter of popping down to the shop floor and asking the engineers. But in a globalised supply chain, you can only get the knowledge your suppliers are willing to give away.

And that is generally not much, when looking with the eye of an LCA practitioner. For an LCA, you need in-depth understanding of processes and materials. For suppliers, this means revealing information that is better off staying confidential, because it can reduce their bargaining power. Once one knows about the quantities of materials, the distances over which they are shipped, the quantities and types of energies used in the processes and the details of the production waste, it only takes a bit of knowledge of the industry sector to retrace how much this all cost.

Of course, manufacturers usually already have some of that knowledge, since they probably thoroughly scanned the sector before they selected a specific supplier. But still, how can we trust one another enough to exchange the high-quality data needed to do a good LCA? How can we convince the supply chain stakeholders to give it?

That is exactly the problem that imposed itself on one of our client, a global apparel retailer, when they were exploring new types of material for their products. An SME offers a material that is extremely promising for their goal of more sustainable sourcing. But for this SME, revealing any information about their materials and processes, especially while they were still negotiating with a giant potential client, was understandably out of the question.

Open collaboration needs transparency and trust

We were commissioned to conduct an LCA of this new material. The way to get around the confidentiality issue was to do the actual LCA work in cooperation with the SME, and to deliver the results to them. Our actual client would be getting only high-level results and potentially a list of red flags.

Getting the supplier to openly share sensitive data was greatly helped by actually going on-site, visiting the factory and getting to know the people and how they work. Once collaboration started, we communicated frequently and transparently about how we understood the data, our first findings and any hotspots detected. This helped them understand what can be achieved with an LCA, so their confidence in the process grew.

Thanks to the extra freedom gained by this trust, we were able to dig deep into the production process: each step was thoroughly described, with inputs, transports, energy, waste and how they tie in with the next step in the process.

We were able to demonstrate to the manufacturer where the strength of their product lies and where the hotspots of their processes were. For a technology that was still under development at the time, this was valuable information. They were, for example, wondering about investing in more energy-efficient machinery for one process. Realising that this particular point was an environmental hotspot gave more arguments in the favour of the investment.

Even more, by pointing out the hotspots in the material content, they were given arguments to discuss technical points with their own client, which led to increased environmental benefits by slightly changing the initial requirements. And on the LCA side, being able to discuss all kinds of possible technical alternatives allowed us to define all the sensitivity scenarios that could affect the results and test them thoroughly, which makes the findings more robust.

Once our contracts at the SME got the grasp of what information LCA could bring, a summary of the findings was prepared with them. All relevant environmental information was disclosed, but no sensitive data was revealed.

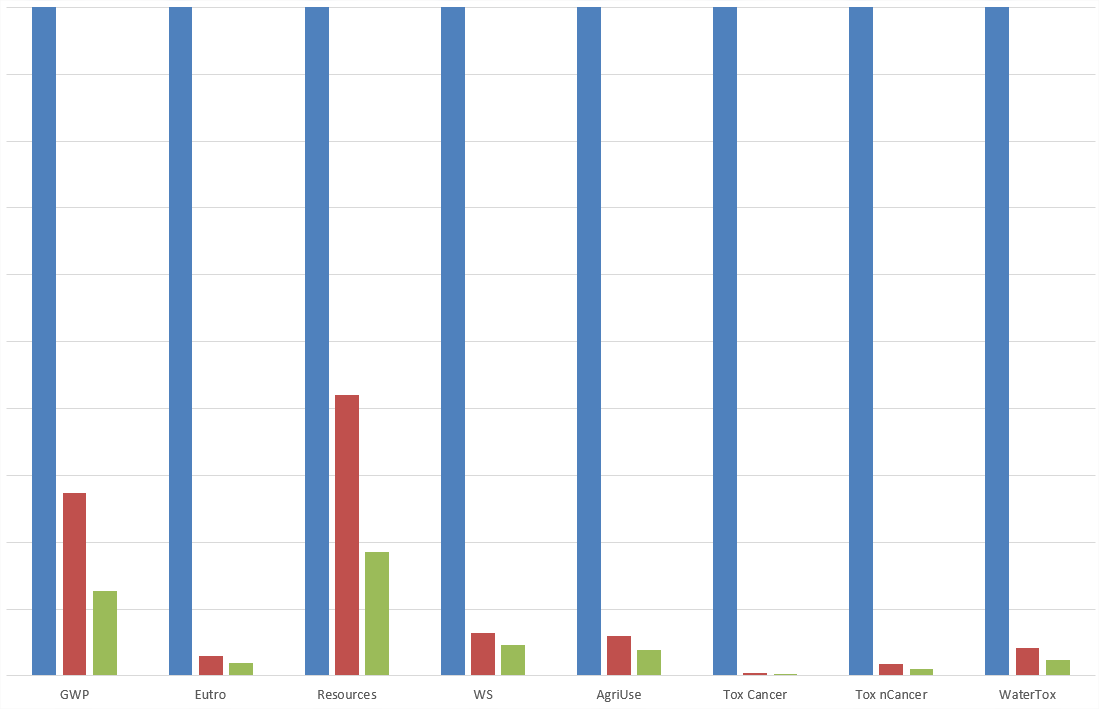

IMAGE: Overall comparative results presented to the client

One-time exercise, or a way of collaboration with huge potential?

Today, our client is introducing the new material on the market, with sufficient environmental information to back up their communication campaign.

This was initially a one-time exercise, between one manufacturer and one of their suppliers. But what if other sectors of industry have an interest in this product, as they have? How can the information gathered be reused without going through the whole process again? The concept of distributed ledger technology, described by Bo Weidema and Manuel Klarmann on the 2.-0 LCA consultants blog, offers an interesting way to expand this type of collaboration. This approach can show reliable and robust calculated results and high-level conclusions. It can even include a statement from the review panel to potential users of a material. But in the end, the supplier’s trade secrets are still protected.

Jori Coustillas

Digital Solutions Expert

I believe companies and organisations need to make drastic changes in the way they do business. In my opinion, LCA is the best tool to help people focus on actually relevant changes. It can help companies steer in more sustainable directions without falling for obvious, but sometimes misleading, options.