Real-time, large-scale LCA with ECOFACT

The demand for life cycle information is increasing at an accelerating rate, and these demands are coming from a growing number of actors and stakeholders. Organizations want to use their life cycle assessment (LCA) results to improve the eco-profile of their products and the sustainability performance of their operations. And consumers are looking for reliable sustainability information to make informed purchasing decisions. All this information can only be provided by scaling up massively. ECOFACT is developing one way to do so.

Achieving fast, scalable LCA capabilities

Collecting and modelling life cycle data is a time-consuming and cost-intensive approach. For companies looking to do LCAs for their whole product portfolios (sometimes containing thousands of products), the traditional LCA approach is no longer feasible. It has become necessary to scale up LCA. This scaled-up LCA also needs to be flexible to update, because data can get outdated quickly. For instance, energy efficiency can improve or quantities might change, and the LCA models need to be updated with the new information.

Automation and digitization can enable data collection and modelling at large scales and make life cycle information widely available. One way PRé is working on scaling up LCA is by joining with a large number of actors within the ECOFACT project.

ECOFACT: enabling real-time LCA through digital technologies

The EU-funded ‘ECO-innovative energy FACTory management’ (ECOFACT) project strives to provide a digital platform for manufacturing companies. They can use it to optimize their production systems in terms of energy, costs, resources and life cycle impacts.

Specifically, the digital platform will provide a manufacturing decision support system based on dynamic LCA and life cycle costing (LCC), which will enable factories to assess and optimize their energy and environmental performance. The platform will also incorporate a prognosis-based energy and resource management system for predictive production planning and maintenance.

Advanced internet-of-things (IoT) technologies will be used to collect the relevant data from the four manufacturing plants that are part of the project consortium, in near real-time. In particular, sensors deployed in the factories will continuously monitor the energy and materials consumption of the manufacturing processes. This ongoing data collection will feed the ECOFACT platform in specific time intervals. The ECOFACT platform will, in return, provide decisions and insights on optimizing the factories’ processes.

After the development of the platform is complete, it will be demonstrated and tested for a year in the four demo factories. The digital platform will result in the introduction of a novel green marketing approach, through the concept of the real-time life cycle environmental and energy signature.

PRé and ECOFACT

PRé’s role in the project is twofold. First, PRé is responsible for creating flexible parameterized LCA and LCC models in the SimaPro online platform. These models will be able to be updated in real time with data from the IoT devices deployed in the factories. The real-time calculation and assessment of life cycle impacts will enable real-time decisions from the digital platform.

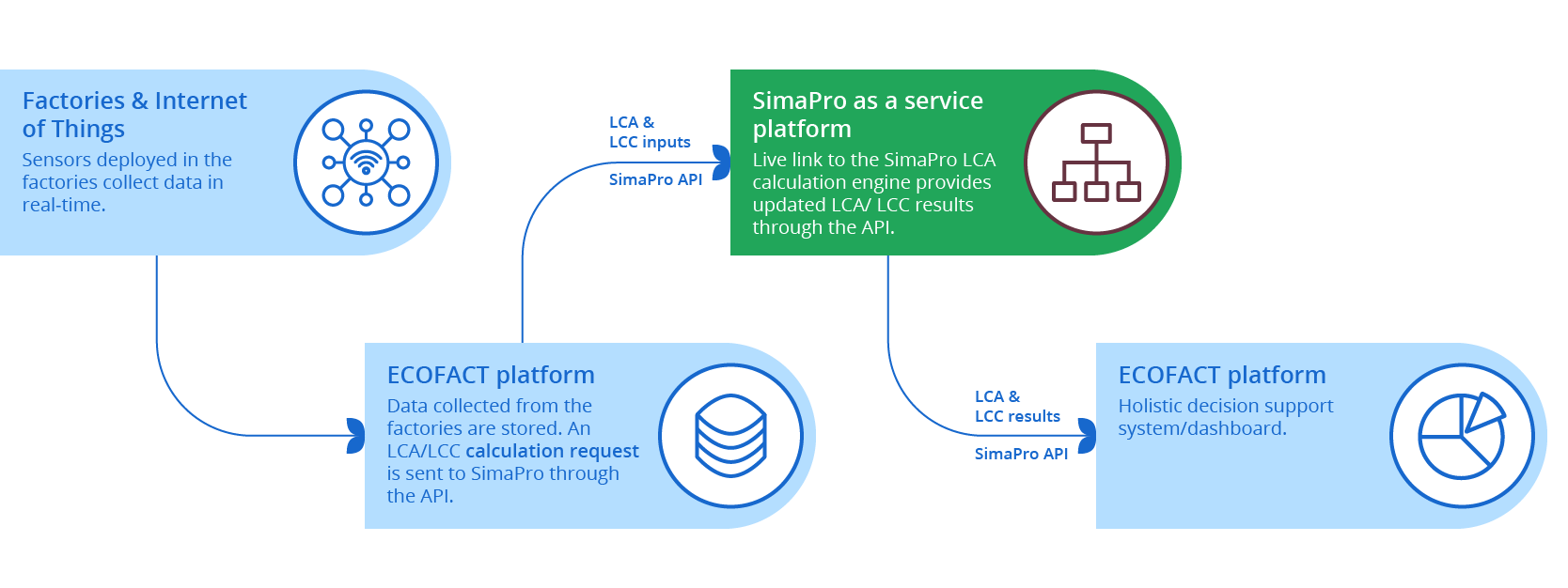

Secondly, PRé is responsible for providing the LCA tools – the SimaPro online platform and SimaPro API – as well as for creating a ‘live link’ between the SimaPro LCA calculation engine and the ECOFACT platform using the SimaPro API. This makes dynamic LCA and LCC calculations feasible, even at such a large scale. The ECOFACT platform will continuously collect and store the key LCI data gathered from the IoT devices deployed in the factories. The platform will then connect directly to the SimaPro calculation engine through the SimaPro API to request updated LCA results.

Unlocking new insights with real-time LCA

Real-time LCA will not only provide the environmental performance snapshot that traditional LCA delivers, but also new insights on an hourly, daily, monthly and yearly basis. These new temporal insights can reveal potential environmental burdens and opportunities that couldn’t be observed otherwise. For example:

- Seasonal variations in environmental performance. For instance, when a factory performs better during the summer months due to lower heating needs or the use of a more renewable electricity mix.

- Daily or even hourly variations in the life cycle impacts of a factory due to changes in the settings and operational parameters of the production machineries.

- Downtime in assembly lines or production processes that affects the environmental performance of a factory.

Sometimes, interpreting these insights is not easy. Imagine a factory has a better environmental impact today than yesterday, while the output of the factory remained the same. What are the reasons for that? Was it due to maintenance in an assembly line? Was there more scrap generated due to changes of the operational parameters of a tool? Or was there an external reason, like weather conditions, that affected some production parameters? Thinking this through could lead to the identification of patterns that otherwise would be not possible to find.

Targeting your performance with new improvement opportunities

The potential new insights can unlock improvement opportunities that would not have been foreseen with the traditional, static LCA approach. New insights can lead to targeted action, directly applied to improve the factory’s environmental performance. For example:

- Changes in production planning. For instance, shifting production to specific days of the week or even specific hours during the day when LCA impacts are minimized.

- Shifting energy-intensive production processes to days and times with favorable weather forecasts.

- Scheduling machine maintenance for certain days or months, and perhaps changing the maintenance frequency based on the environmental results of the factory right after maintenance.

Because any changes in the factory are monitored and evaluated real-time and in an automated way, this creates a positive feedback loop for further targeted improvements, with minimum data gathering effort.

A real-time LCA open source toolkit

So far, we’ve set the goal and scope of the four demo industrial sites, with special attention to which data points will be updated dynamically and how often that update will be. The identified data points have been mapped to data sources from the demo industries, such as supervisory control and data acquisition (SCADA), building management system (BMS), manufacturing execution system (MES), or new sensors to be installed in the factory. The results achieved so far will be part of the public deliverable D4.1 that PRé is leading, named “Mapping of data sources for dynamic LCA/LCCA”, which is due end of 2021.

PRé’s main deliverables, due in 2022, are the parameterized LCA models for the demo factories and an open source toolkit on how to perform a real-time LCA. The toolkit will describe the detailed steps and requirements for setting up a live link between the SimaPro calculation engine and the ECOFACT platform – or any other software – using the SimaPro API. This will allow users to do real-time life cycle assessment and life cycle costing analysis.

More information about the ECOFACT project (Grant Agreement number 958373): https://ecofact-project.eu/

Georgios Pallas

Expert

I believe that with the right use of data, metrics and tools we can create a bright future for all. I get energy by delving into data and finding insights that can help organizations make better decisions towards sustainability and competitiveness in a quickly changing world.