What can the Internet of Things do for sustainability?

Connecting products to the Internet of Things (IoT) makes it possible to monitor and act on data from the field. This could help fill important information gaps when it comes both to realizing a circular economy and carrying out life cycle assessment (LCA). But the IoT also comes with its own environmental challenges. In this article, Emilia Ingemarsdotter, Analyst at PRé, shares insights from her recent PhD research and introduces the ECOFACT project, where PRé is doing cutting-edge work on IoT-enabled dynamic LCA.

The IoT as an enabler for the circular economy

The ‘Internet of Things’ (IoT) is a popular term to describe the trend towards more widespread digital connectivity between physical things and between people and things. By endowing products with tracking and sensing capabilities, and connecting them to the internet, we can get new insights into their lifecycles. Where do they actually end up? How are they used? What is their remaining lifetime at a certain moment in time? In the context of a circular economy, where the goal is to use products and materials to their fullest potential, this could be very valuable information. At the start of my PhD, I asked myself whether these opportunities that the IoT creates for the circular economy could be categorized in useful ways. The goal was to help designers and business managers to explore IoT-enabled strategies for realizing a circular economy. I identified five key IoT capabilities: tracking, monitoring, control, optimization, and design evolution.

Five key IoT capabilities that support circular strategies

- Tracking. Information is available about a product’s identity, location, or unique composition.

- Monitoring. Information is available about a product’s use, condition, or environment. This includes alerts and notifications.

- Control. Product functionality can be controlled through software, based on predefined options. This includes pushing regular updates.

- Optmization Goal-based improvements to operations are supported through the use of advanced algorithms.

- Design evolution. The design of a product or service can be improved based on data feedback from other lifecycle phases. This includes functional upgrades and the development of new products and services.

What is happening in practice?

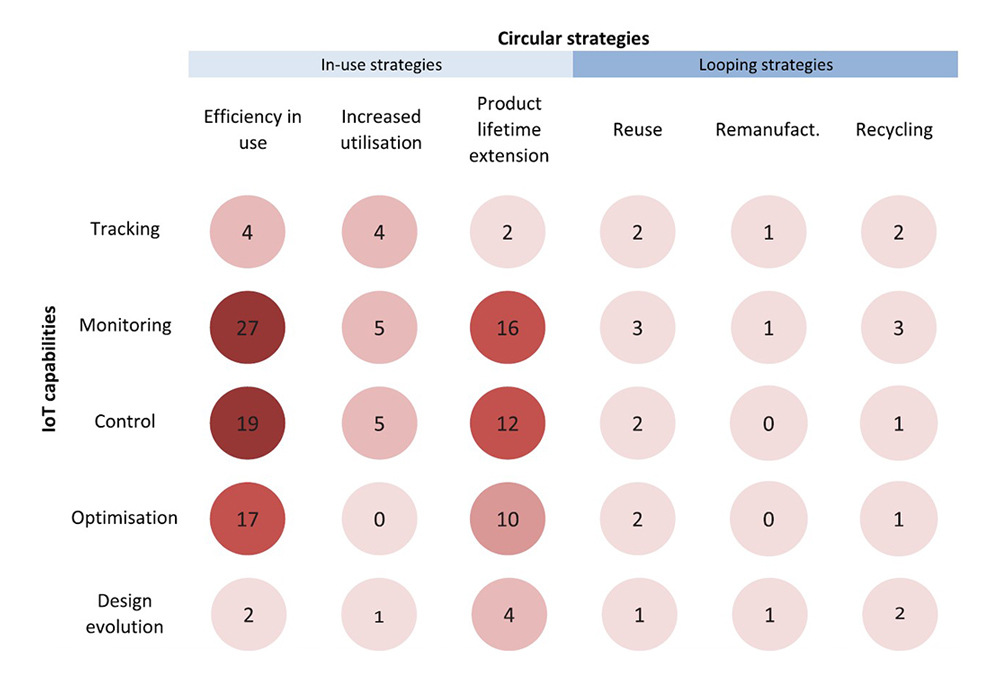

Together with my PhD advisors, Prof. Ruud Balkenende and Dr. Ella Jamsin, I also studied many examples of the implementation in practice of IoT-enabled strategies for realizing a circular economy. We mapped these examples according to the types of IoT capabilities used and the circular strategies they enabled. This resulted in the heat map below that shows how implementation in practice relates to the opportunities presented in literature. I found that the most commonly applied strategy is to use the IoT to improve energy efficiency in the product’s use stage. There were also quite a few examples where the IoT was used to support longer product lifetimes through condition-based and predictive maintenance. By contrast, there were fewer examples where companies leveraged IoT capabilities to support reuse, remanufacturing, or recycling.

I also interviewed many company representatives about the challenges they face when trying to realize the opportunities that the IoT offers to circular and sustainable innovation. A key finding here was that the technical challenges are only one part of the equation. Both IoT and circularity projects often require multiple changes at once for a company: to the product or service design, the business model, and the organization itself. It is thus important to see the larger context in which the IoT solution will be applied. The organization needs to have a clear vision of what they want to achieve. In addition, new collaborations need to be established, user research needs to be carried out, and processes need to be developed to enable the collection and analysis of structured data. These findings can be explored in more detail in the following publications: Ingemarsdotter et al. (2020) and Ingemarsdotter et al. (2021a). The latter paper is a collaboration with colleagues from Linköping University in Sweden, in which we focused specifically on how companies can implement condition-based maintenance.

Quantifying the net environmental impact

Seeing the larger context also includes understanding the potential of a specific solution to actually reduce environmental impacts. This requires an evaluation of the net environmental consequences. On the one hand, the IoT solution can bring environmental savings. On the other, there will be added impacts, both from additional electronics and from processing and transferring of data. LCA thus becomes a critical tool for understanding what is sensible from an environmental standpoint. An article that I wrote together with my PhD advisors and colleagues from RISE Research Institutes of Sweden about connected truck tires gives an example of how this can be done: Ingemarsdotter et al (2021b).

Sensor data feeds dynamic LCAs for continuous impact assessment

In my new role at PRé, I am continuing to explore how the IoT can enable sustainability within the ECOFACT project, which is funded by the EU H2020 program. ECOFACT stands for “ECO-innovative Energy FACTory Management platform based on improved dynamic LCA and LCCA towards holistic manufacturing sustainability.” In this project, a large number of organizations are coming together to develop a methodology and build a digital platform that can help factories optimize their energy performance and reduce their overall environmental footprint. PRé’s role includes building flexible LCA and LCC (life cycle costing) models that can be updated dynamically with data from IoT devices in the factories. This means that the impacts will be calculated based on near real-time data, and it will be possible to see how the impact changes over time. This can lead to a better understanding of which parameters influence environmental and economic performance and make it possible for companies to monitor the effect of continuous improvements.

Only the beginning

It is clear that we are only at the beginning of the development of IoT solutions that support the circular economy, LCA, and sustainability more generally. And many interesting questions remain: How will the access to dynamic LCA results change environmental management in companies? How will data be shared between different organizations in the supply chain? And how should ‘smart’ products be designed to really be part of the solution?

More information about the ECOFACT project (Grant Agreement number 958373): https://ecofact-project.eu/

Emilia Ingemarsdotter

Consultant

Emilia worked at PRé between 2021 and 2024. As a Consultant, she worked on many projects in the fields of LCA, decarbonization, and circular economy – often with a focus on digitalization – and provided PEF trainings.